Highly efficient filters for your oil or gas application

Manufacturers across the oil and gas industry trust Porex for its broad portfolio of filtration media. From bonded fiber to porous plastic media, customizable filtering solutions from Porex can meet your specific needs.

Our filtration media for the oil and gas industry are:

- Designed for high filtration efficiencies

- Self-supporting media to enable easier assembly

- Offer options for water or oil separation

- Manufactured to your specific application requirements to ensure highly efficient filtration.

Water Separation Media

Separate water easily from your oil or gas streams

Protection Vents

Protect your gearbox venting system

Water Separation Media

Separate water easily from your oil and gas streams

From bonded fiber to sintered porous media, Porex creates media to separate or filter water from oil and gas streams.

Specifically designed for your oil and gas application, our water separation media:

- Reduce material usage – Porex bonded fiber material products can replace the need for multiple medi layers commonly found in oil/water separation filters.

- Self support – Filters can be self-supporting and customized into various shapes and sizes.

Protection Vents

Protect your gearbox venting system

Porex provides standard and custom-finished gearbox venting solutions for your gearbox challenges. These venting and filtration solutions can vary from simple protection vents to vents containing media for specific moisture or fume absorption to vents for separating oil mists. The material is customizable to your specific gearbox venting application and can incorporate functional additives for optimized performance.

POREX Virtek® PTFE Membrane — Typical Properties

| Item Number | IP Rating † | WEP* Typical mbar | Typical Airflow l/hr/cm² @70mbar | Filtration Efficiency** >99.99% | Thickness mm | Max Operating Temp °C | UL-94/746C | Salt Fog$ |

|---|---|---|---|---|---|---|---|---|

| PMV10 | 64,67 | 270 | 125 | 0.5 µ | 0.13 | 260°C | V-0/f2 | No pen. |

| PMV10L*** | 64,67 | 270 | 85 | 0.5 µ | 0.3 | 100°C | – | No pen. |

| PMV15 | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | V-0/f2 | No pen. |

| ‡PMV15T | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | – | No pen. |

| PMV20 | 64,65,68 | 520 | 34 | 0.1 µ | 0.25 | 260°C | V-0/f2 | No pen. |

| PMV25 | 65,67,68 | 750 | 15 | 0.2 µ | 0.1 | 260°C | V-0/f2 | No pen. |

| PMV27 | 65,66,67,68 | 1000 | 5.0 | 0.1 µ | 0.19 | 260°C | V-0/f2 | No pen. |

| PMV30 | 65,66,67,68 | 1000 | 4.5 | 0.1 µ | 0.25 | 260°C | V-0/f2 | No pen. |

† IEC std. 60529; IP 68 is a user defined and results must be verified by the user

*WEP = Water Entry Pressure

** According to IEST RP-CC007.2 2009

$ASTM B117-11 test method

***Laminated polyolefin mesh backing

‡ Oleophobic, AATCC TM 118 – Grade 8 – other membranes can also be treated to meet Grade 8 upon request

Properties are typical and not meant for specifications. Selected options and adhesives may effect properties

RoHS, WEEE, REACH Compliant (PFOA Free)

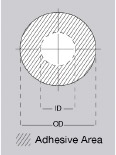

STOCK PRODUCT OFFERING BY MATERIAL SERIES – POREX Virtek® ADHESIVE DISCS

| Dimensions | ||||

|---|---|---|---|---|

| OD x ID (mm)* | PMV10L | PMV15 | PMV20 | PMV30 |

| 7.0 x 3.0 (N) | PMV10LN | PMV15N | PMV20N | PMV30N |

| 10.0 x 6.0 (P) | PMV10LP | PMV15P | PMV20P | PMV27P** |

| 12.7 x 7.1 (W) | PMV10LW | PMV15W | PMV20W | PMV30W |

| 20.0 x 13.0 (C) | PMV10LC | PMV15C | PMV20C | PMV30C |

| 12.7 x 7.1 (W) | PMV15WH# | |||

| 12.7 x 7.1 (W) | PMV15TWH## |

*1000 discs/roll

**PMV27 will become the new standard offering – other sizes will follow

# With high temperature adhesive (good to 150 °C )

## Oleophobic Treated and high temperature adhesive (good to 150 °C )

N, P, W & C are size codes.

Many other standard and custom sizes available. Contact Porex for more information

Adhesive Vent AvailableStandard Sizes

| Available Sizes | Available Sizes |

|---|---|

| OD x ID (mm) | Parts Across |

| 5 x 2 | 4 |

| 7 x 3* | 1 |

| 7.6 x 3.3 | 1 |

| 7.6 x 3.3 | 4 |

| 10 x 6* | 1 |

| 10 x 6 | 5 |

| 12.7 x 7.1* | 1 |

| 14 x 8 | 1 |

| 20 x 13* | 1 |

| 21 x 16 | 1 |

| 25.4 x 19 | 1 |

| 30 x 25 | 1 |

| 40 x 32 | 1 |

| 40/19.5 x 30/9.5** | 6 |

**Rectangular format

Longer lead times for non-stocked items

Custom sizes available upon request

POREX Virtek® PTFE Vent Plugs — Typical Properties

| Item Number | Diameter mm (in.) | Thickness mm (in.) | WEP* mbar | IP Rating† | Typical Vent Airflow l/hr @70mbar | Max Operating Temp °C | Filtration Efficiency (99.99%) | UL-94 Rating |

|---|---|---|---|---|---|---|---|---|

| PD103032 | 3.2 (1/8″) | 3 (1/8″) | 450 | 64,67,68 | 1 | 260°C | 0.5 µ | 5VA, f1 |

| PD103063 | 6.3 (1/4″) | 3 (1/8″) | 450 | 64,67,68 | 3.8 | 260°C | 0.5 µ | 5VA, f1 |

*WEP = Water Entry Pressure

† IEC std. 60529; IP 68 is a user defined and results must be verified; product has not been specifically tested – passing is based on results from similar products

Assembly methods include: press fit, over-molding, compression seal, adhesive bonding or flange welding.

Numerous custom and standard options available. Please contact your local Porex sales representative to determine what is available.

Properties are typical and not meant for specifications.

RoHS, WEEE, and REACH Compliant (PFOA Free)

Related Resources:

![]() Datasheet: POREX Virtek IP Rated Protection Vents

Datasheet: POREX Virtek IP Rated Protection Vents

![]() Datasheet: PTFE Fact Sheet

Datasheet: PTFE Fact Sheet

![]() Datasheet: Porex PTFE Ingress Protection Test Report

Datasheet: Porex PTFE Ingress Protection Test Report

![]() Demonstration video: Demo of Porehttps://learn.porex.com/ip-rated-protection-vents/Virtek-PTFE-Common-Joining-Techniquesx Virtek PTFE Common Joining Techniques

Demonstration video: Demo of Porehttps://learn.porex.com/ip-rated-protection-vents/Virtek-PTFE-Common-Joining-Techniquesx Virtek PTFE Common Joining Techniques

![]() Demonstration video: Hydrophobicity and handling properties: POREX Virtek PTFE vs. expanded PTFE

Demonstration video: Hydrophobicity and handling properties: POREX Virtek PTFE vs. expanded PTFE

![]() Demonstration video: Durability comparison of POREX Virtek PTFE vs. expanded PTFE

Demonstration video: Durability comparison of POREX Virtek PTFE vs. expanded PTFE

![]() Demonstration video: Dangers of not venting a sealed enclosure

Demonstration video: Dangers of not venting a sealed enclosure

![]() Demonstration video: Keep electronics dry and protected with POREX Virtek PTFE vents

Demonstration video: Keep electronics dry and protected with POREX Virtek PTFE vents