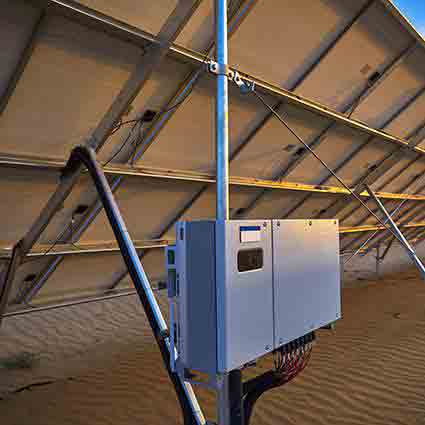

保持风能和太阳能系统的有效运行

Porex 的防护透气膜和过滤器帮助可再生能源系统更可靠地运行。我们的透气膜防水、防尘,防污垢,并允许设备在加热和冷却循环过程中呼吸。我们的过滤器可根据应用定制过滤流体或空气。

与竞争对手的透气膜相比,我们用于风能和太阳能应用的POREX® Virtek™ PTFE 防护透气膜:

- 更坚固耐用– 与膨体 PTFE 相比,POREX Virtek™ 烧结 PTFE 材料能够承受更多的操作而不会损坏。

- 易于焊接到塑料外罩上,可以更安全地粘接,从而减少泄漏。

- 可根据您的应用规格进行定制, 包括形状和性能。

系统防护透气膜

在任何天气中保持系统平稳运行

变速箱透气膜和过滤器

保护您的变速箱透气系统

系统防护透气膜

在任何天气中保持系统平稳运行

用于风能和太阳能应用的 Porex® Virtek™ 防护透气膜旨在保持系统在任何气候或天气条件下平稳有效地运行。

POREX Virtek™ 透气膜凭借其烧结结构, 易于组装,无需繁琐的装配说明即可进行处理和焊接。

我们针对风能和太阳能应用的防护透气膜可以:

- 均衡压力 – 减少压力积聚并允许热量从外罩中逸出,因为透气结构充当减压阀并保护外罩密封件免于过早失效。

- 防止污染 –材料可防止水、污垢、油和其他液体进入外罩。

| 库存产品发售 – 带背胶切片 | |||||

| 尺寸 | 材料系列 | ||||

|---|---|---|---|---|---|

| 外径/内径(mm)* | PMV10L | PMV15 | PMV20 | PMV30 |  |

| 7.0/3.0 (N) | PMV10LN | PMV15N | PMV20N | PMV30N | |

| 10.0/7.0 (I) | PMV10LI | PMV15I | PMV20I | PMV30I | |

| 12.7/7.1 (W) | PMV10LW | PMV15W | PMV20W | PMV30W | |

| 20.0/13.0 (C) | PMV10LC | PMV15C | PMV20C | PMV30C | |

| 尺寸 | 材料系列 | |

|---|---|---|

| 外径/内径(mm)* | PMV15 | 特征 |

| 12.7/7.1 (W) | PMV15WH | 耐高温背胶 |

| 12.7/7.1 (W) | PMV15TWH | 疏油性,同时具有耐高温的背胶 |

| * 1000片/卷 N、I、W 与 C 是尺寸代码。 许多其他标准和自定义尺寸可用。请联络 Porex。 |

||

| POREX® Virtek™ PTFE 膜应用材料 — 典型特性 | ||||||||

| 应用材料 | IP 等级† | WEP mbar | 气流 l/hr/cm² @70mbar | 过滤效率 **>99.99% | 厚度 mm | 最高操作温度 °C | UL-94/746C* | 盐雾 |

|---|---|---|---|---|---|---|---|---|

| PMV10 | 64,67 | 270 | 125 | 0.5 µ | 0.13 | 260°C | V-0/f2 | 优异 |

| PMV10L*** | 64,67 | 270 | 85 | 0.5 µ | 0.3 | 100°C | – | 优异 |

| PMV15 | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | V-0/f2 | 优异 |

| ‡PMV15T | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | – | 优异 |

| PMV20 | 64,65,68 | 520 | 34 | 0.1 µ | 0.25 | 260°C | V-0/f2 | 优异 |

| PMV25 | 65,67,68 | 750 | 15 | 0.2 µ | 0.1 | 260°C | V-0/f2 | 优异 |

| PMV30 | 65,66,67,68 | 1000 | 4.5 | 0.1 µ | 0.25 | 260°C | V-0/f2 | 优异 |

| WEP = 进水压力 符合 RoHS, WEEE, REACH **根据 IEST RP-CC007.2 2009 ***层压聚烯烃网格支撑膜 † IEC 标准 60529,IP 68 是用户定义的测试;将通过条件依赖 ‡疏油性等级8,AATCC TM 118 参数只是典型的,不代表正式规格。 属性仅限膜而言,选择的选项和粘胶可能会影响属性。 可根据要求提供测试结果 |

||||||||

| POREX® Virtek™ PTFE 透气膜 — 典型特性 | |||||||

| 部件 # | 直径 mm | 厚度 mm | WEP mbar | IP 等级† | 透气流速l/hr/cm² @70mbar | 最高操作温度°C | UL-94 等级 |

|---|---|---|---|---|---|---|---|

| PD103032 | 3.2 | 3 | 450 | 64,67,68 | 1 | 260°C | 5VA,f1 |

| 插头符合 UL-94 5VA和F1 等级。 装配方法包括:压配合、包覆成型、压缩密封或法兰焊接。 |

|||||||

| 粘合剂透气膜可用尺寸 | |

| 可用尺寸 | |

|---|---|

| 外径 (以毫米计) | 内径(以毫米计) |

| 7 | 3 |

| 10 | 7 |

| 10.2 | 6.5 |

| 11 | 7 |

| 12.7 | 7.1 |

| 13 | 10 |

| 14.8 | 11 |

| 14.8 | 7 |

| 15.8 | 9 |

| 16 | 11 |

| 18 | 13 |

| 18.6 | 10.6 |

| 19.1 | 11.5 |

| 20 | 13 |

| 25.4 | 19 |

| 50 | 30 |

|

*高亮显示的行表示库存商品。 可根据要求定制尺寸 |

|

相关资源:

![]() 数据表:PTFE 资料便览

数据表:PTFE 资料便览

![]() 演示视频: 疏水性和处理性能:POREX Virtek™ PTFE 对比膨体 PTFE

演示视频: 疏水性和处理性能:POREX Virtek™ PTFE 对比膨体 PTFE

![]() 演示视频: 耐久性比较:POREX Virtek™ PTFE 对比膨体 PTFE

演示视频: 耐久性比较:POREX Virtek™ PTFE 对比膨体 PTFE

![]() 演示视频: 密封外罩不透气的危险

演示视频: 密封外罩不透气的危险

![]() 演示视频: 保持电子设备干燥并使用 POREX Virtek™ PTFE 透气膜保护

演示视频: 保持电子设备干燥并使用 POREX Virtek™ PTFE 透气膜保护

变速箱透气膜和过滤器

保护您的变速箱透气系统

Porex 为您的变速箱挑战提供多种透气和过滤解决方案。这些透气和过滤解决方案可以从简单的自粘性透气膜到含有特定水分或烟雾吸收介质的透气膜到用于分离油雾的透气过滤器。这些材料可根据您的特定变速箱透气应用进行定制,并可包含功能性添加剂以优化性能。

| POREX® Virtek™ PTFE 膜应用材料 — 典型特性 | ||||||||

| 应用材料 | IP 等级† | WEP mbar | 气流 l/hr/cm² @70mbar | 过滤效率 **>99.99% | 厚度 mm | 最高操作温度 °C | UL-94/746C* | 盐雾 |

|---|---|---|---|---|---|---|---|---|

| PMV10 | 64,67 | 270 | 125 | 0.5 µ | 0.13 | 260°C | V-0/f2 | 优异 |

| PMV10L*** | 64,67 | 270 | 85 | 0.5 µ | 0.3 | 100°C | – | 优异 |

| PMV15 | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | V-0/f2 | 优异 |

| ‡PMV15T | 64,67 | 380 | 70 | 0.4 µ | 0.18 | 260°C | – | 优异 |

| PMV20 | 64,65,68 | 520 | 34 | 0.1 µ | 0.25 | 260°C | V-0/f2 | 优异 |

| PMV25 | 65,67,68 | 750 | 15 | 0.2 µ | 0.1 | 260°C | V-0/f2 | 优异 |

| PMV30 | 65,66,67,68 | 1000 | 4.5 | 0.1 µ | 0.25 | 260°C | V-0/f2 | 优异 |

| WEP = 进水压力 符合 RoHS, WEEE, REACH **根据 IEST RP-CC007.2 2009 ***层压聚烯烃网格支撑膜 † IEC 标准 60529,IP 68是用户定义的测试;将通过条件依赖 ‡疏油性等级8,AATCC TM 118 参数只是典型的,不代表正式规格。 属性仅限膜而言,选择的选项和粘胶可能会影响属性。 可根据要求提供测试结果 |

||||||||

| 库存产品发售 – 带背胶切片 | |||||

| 尺寸 | 材料系列 | ||||

|---|---|---|---|---|---|

| 外径/内径(mm)* | PMV10L | PMV15 | PMV20 | PMV30 |  |

| 7.0/3.0 (N) | PMV10LN | PMV15N | PMV20N | PMV30N | |

| 10.0/7.0 (I) | PMV10LI | PMV15I | PMV20I | PMV30I | |

| 12.7/7.1 (W) | PMV10LW | PMV15W | PMV20W | PMV30W | |

| 20.0/13.0 (C) | PMV10LC | PMV15C | PMV20C | PMV30C | |

| 尺寸 | 材料系列 | |

|---|---|---|

| 外径/内径(mm)* | PMV15 | 特征 |

| 12.7/7.1 (W) | PMV15WH | 耐高温背胶 |

| 12.7/7.1 (W) | PMV15TWH | 疏油性,同时具有耐高温的背胶 |

| * 1000片/卷 N、I、W & C 是尺寸代码。 许多其他标准和自定义尺寸可用。请联络 Porex。 |

||

| POREX® Virtek™ PTFE 透气插块 — 典型特性 | |||||||

| 部件 # | 直径 mm | 厚度 mm | WEP mbar | IP 等级† | 透气流速l/hr/cm² @70mbar | 最高操作温度°C | UL-94 等级 |

|---|---|---|---|---|---|---|---|

| PD103032 | 3.2 | 3 | 450 | 64,67,68 | 1 | 260°C | 5VA,f1 |

| 插头符合 UL-94 5VA和F1 等级。 装配方法包括:压配合、包覆成型、压缩密封或法兰焊接。 |

|||||||

| 粘合剂透气膜可用尺寸 | |

| 可用尺寸 | |

|---|---|

| 外径 (以毫米计) | 内径(以毫米计) |

| 7 | 3 |

| 10 | 7 |

| 10.2 | 6.5 |

| 11 | 7 |

| 12.7 | 7.1 |

| 13 | 10 |

| 14.8 | 11 |

| 14.8 | 7 |

| 15.8 | 9 |

| 16 | 11 |

| 18 | 13 |

| 18.6 | 10.6 |

| 19.1 | 11.5 |

| 20 | 13 |

| 25.4 | 19 |

| 50 | 30 |

|

*高亮显示的行表示库存商品。 可根据要求定制尺寸 |

|

相关资源:

![]() 数据表:PTFE 资料便览

数据表:PTFE 资料便览

![]() 演示视频: 疏水性和处理性能:POREX Virtek™ PTFE 对比膨体 PTFE

演示视频: 疏水性和处理性能:POREX Virtek™ PTFE 对比膨体 PTFE

![]() 演示视频: 耐久性比较:POREX Virtek™ PTFE 对比膨体 PTFE

演示视频: 耐久性比较:POREX Virtek™ PTFE 对比膨体 PTFE

![]() 演示视频: 密封外罩不透气的危险

演示视频: 密封外罩不透气的危险

![]() 演示视频: 保持电子设备干燥并使用 POREX Virtek™ PTFE 透气膜保护

演示视频: 保持电子设备干燥并使用 POREX Virtek™ PTFE 透气膜保护