What Is the Difference Between ePTFE and Sintered PTFE?

Articles | Automotive | Consumer Goods | Industrial | Life Sciences | Membranes | Vent |

Inside many common products, like cell phones and headlights, live unseen protection vents (sometimes called protective vents). The vents are made out of a durable, versatile material called PTFE, or polytetrafluoroethylene.

In general, porous PTFE is a material that allows air and other gases to pass through while keeping larger molecules, like water, out. Its unique composition makes it ideal for protection vents. Inside a cell phone, for example, a thin, dime-sized PTFE film sits behind the microphone and acts as a vent, allowing air to flow through while repelling contaminants like water and dust.

Talk with a Material Science Expert

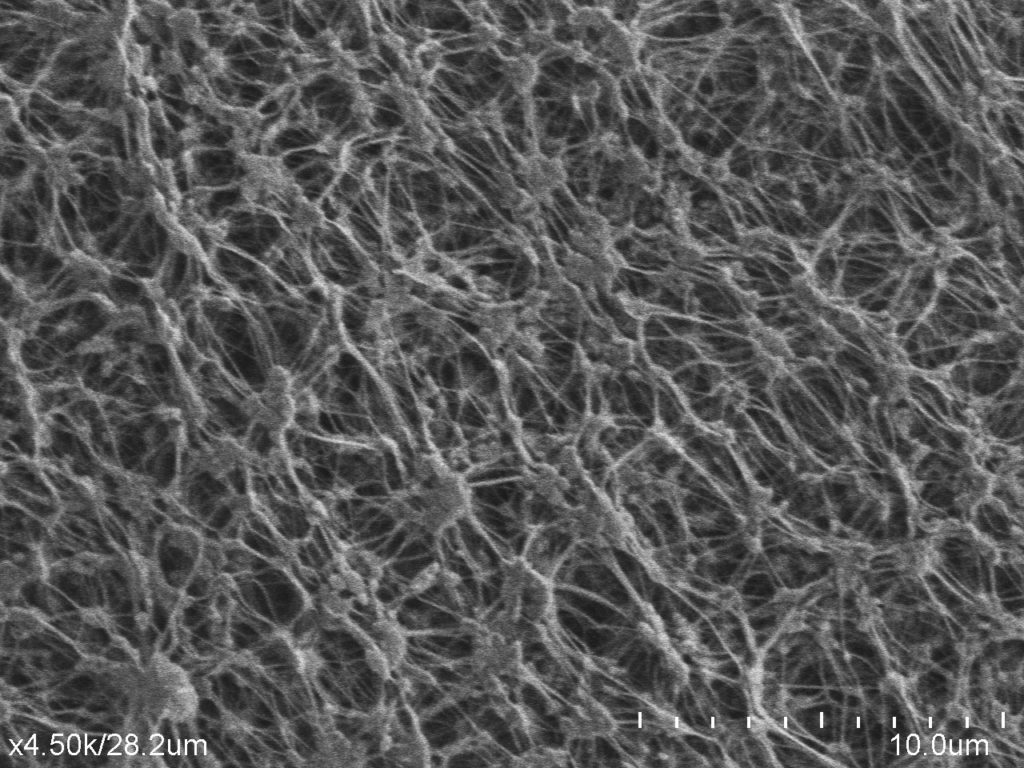

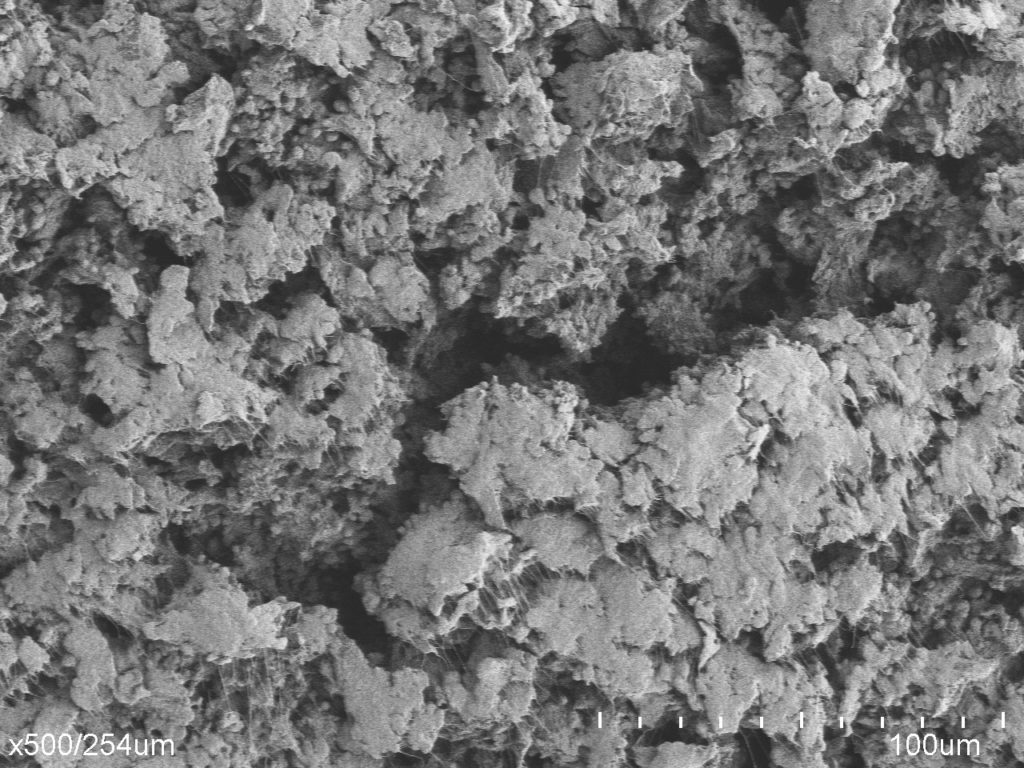

The scanning electron microscope (SEM) images below offer a unique glimpse into the microstructures of both expanded PTFE (ePTFE) and sintered PTFE. These high-resolution images allow us to grasp the intricate details that set these materials apart visually. As we explore their differences, we gain valuable insights into how these structural variances influence their performance and suitability for various applications.

Expanded PTFE vs. sintered PTFE

When it comes to protection vents and barriers within devices, PTFE, or polytetrafluoroethylene, plays a pivotal role. However, not all PTFE is created equal, and it’s crucial to grasp the distinctions between two primary variants: expanded PTFE (ePTFE) and sintered PTFE. These two materials may share a common goal of providing breathable barriers, but their differences are evident in durability, support requirements, airflow characteristics, and water-repellent properties. In this section, we dive into the comparative analysis of these materials, shedding light on the factors that influence product design and engineering choices for optimal performance.

Durability

Expanded PTFE (ePTFE) offers a unique, lightweight structure, with a thickness down to 0.02mm, providing a thin yet effective barrier in sensitive applications. Its delicate nature may require careful handling to maintain its integrity, highlighting its precision-engineered design.

In stark contrast, sintered PTFE exhibits remarkable strength. This difference is palpable; you can feel the sturdiness of the material. Unlike ePTFE, sintered PTFE retains its integrity even when subjected to physical contact, making it a robust choice for various applications.

Support

ePTFE’s nuanced sensitivity necessitates strategic support, often achieved by laminating it to fabric, enhancing its durability without compromising its inherent properties. This approach allows for protective vents that combine the benefits of ePTFE’s permeability with structural integrity. Sintered PTFE, with its inherent strength, doesn’t require additional support. Its ability to be ultrasonically welded to plastic components streamlines the manufacturing process, offering a straightforward solution for various applications.

Air Flow

Airflow is a critical factor in many applications, and ePTFE is designed to offer controlled airflow, which can be particularly advantageous in applications requiring precise air regulation. While contact can affect airflow, this characteristic can be leveraged to fine-tune performance in specialized environments. Sintered PTFE, known for its consistent airflow characteristics, remains unaffected by physical contact, ensuring reliable performance in applications where continuous airflow is essential.

Water Repellent

Both ePTFE and sintered PTFE excel in water repellency. ePTFE uniquely handles water by forming beads that can be easily wicked away, suitable for environments where moisture control is critical. While occasionally, some water may adhere to its surface, this trait can be utilized in applications requiring specific moisture interactions. Sintered PTFE, with its ability to repel water entirely, leaving no residue, provides an added level of protection, especially in settings where any water ingress must be meticulously avoided.

Wrap up

Protection vents made from PTFE components can be found in a variety of electrical, industrial, medical, and consumer applications. As engineers create products, it’s important to understand the difference between ePTFE and sintered PTFE. If you’d like to see the differences, use our Sample Selector to discover Porex Virtek™ firsthand or talk to one of our material science engineers.