Sintered porous plastics innovation expert

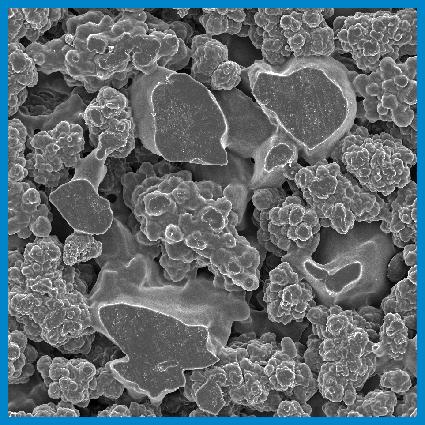

Sintered porous plastic materials are manufactured by Porex using a proprietary process that enables the creation of both 2D and 3D porous polymer components that offer superior strength, durability, chemical resistance, resiliency, and design flexibility across many applications. Made from a variety of thermoplastic materials with varying properties, our materials can be supplied as sheets, rolls, or other geometric formats specific to your filtration, absorption, applicator, venting, diffusing, or wicking needs. Unlike injection molding, the material is not liquified but instead bonded together through controlled heat and pressure that results in a connected pore structure that can be truly tailored to control the flow of particles within the device.

While sintered polypropylene and sintered polyethylene are most commonly recognized and used, there are other types of porous polymers available, such as Polytetrafluoroethylene (PTFE) and Polyvinylidene fluoride (PVDF), which we can help you to select based on your device and the chemical and additive compatibility required.

Talk with a Material Science Expert

Manufacturing process

Sintered porous plastics are created using a combination of heat and pressure to bond the materials together. The objective is not to melt or change the main properties of the material, but to create a porous media where pore size and volume can be strategically manipulated to optimize your device’s performance. This could include functional capabilities such as wicking speed, wicking distance, filtration efficiency, flow resistance, and absorption speed and volume, among others.

Watch the process

Options for customizing sintered porous plastics

Register for Our On-Demand Webinar

Intro to Sintered Porous Plastics

Common applications for sintered porous plastics

Filter

In the field of healthcare, sintered porous plastics can offer filtration capabilities which facilitate measured pharmaceutical delivery of inhalers, nebulizers, spray pumps, and other medical devices. In addition, they can be used to maintain the device’s sterility when utilizing antimicrobial additives.

Apply

Sintered porous plastics can be used to ensure leak-free performance of applicators that spread a fluid, gas, or solid onto a surface or substrate. This could include topical applicators for drug delivery, writing instrument nibs, or cosmetic products which all require unique delivery and transfer of ink or formula.

Vent

Designing protective vents using sintered porous plastics can allow for the escape or release of fumes, a liquid, a gas, or steam in various applications. This could include IV catheters that must vent out air as blood fills the chamber or electronics or batteries that need protection against dust and moisture.

Diffuse

For devices requiring a consistent emission of a gas or liquid over time, sintered

porous plastics can provide a reliable means of diffusion in applications such as air care, insecticides, or even healthcare where bioprocessing spargers diffuse oxygen into cell cultures.

Absorb

For targeted gas detection and air filtration applications, sintered porous plastics can help to absorb various airborne particles that otherwise may impact detection capabilities and/or pose a safety concern for those exposed.

Why do pore size and flow matter?

Learn more in our new technical article

Related Resources

Porex: The Perfect Fit Brochure

Experience Porex’s customizable porous media capabilities. From advanced filtration media to cutting-edge fluid management, our unmatched material science expertise and extensive global manufacturing network help you unlock new frontiers of innovation and efficiency.

Understanding Pore Size Distribution

In this video, learn how to measure the space between the particles and their effect on component performance.

Understanding Pore Volume

Explore the impact of pore volume to better understand its impact on your device’s functionality.

Your Partner in Innovation

Discover how Porex has been a partner in innovation for over 60 years in this video.