Ensure properly disinfected air with Porex Virtek reflective media lining your UV air disinfection products

With the recent heightened awareness around clean indoor air, it has become clear that utilizing a UVC system within an air handling unit has become a common and effective solution. UVC energy is proven to deactivate most pathogens; however, to be effective, the UV energy must be uniformly dispersed within the reaction chamber. This is where Porex Virtek PTFE reflective media excels.

Porex Virtek offers:

- Reflectivity rates of up to 97%

- Almost 100% Lambertian (diffuse) reflectivity to ensure extremely uniform UVC energy distribution within the reaction chamber

- Minimized hot and cold spots within the reaction chamber

- Up to 4x higher flux in a closed system versus aluminum

- Increased effective pathogen deactivation rates, by up to 4X versus other reflective media

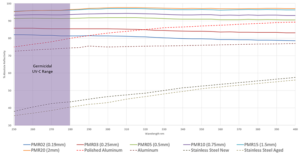

- High reflectivity and durability down to 200 nm UVC wavelength

Optimize efficiency and ensure maximum pathogen disinfection within your UV air disinfection system

UV disinfection chambers lined with Porex Virtek PTFE high-reflectivity media feature the Intensified with Porex Virtek logo, highlighting the efficacy of high reflectivity. Review our technical specifications and supporting technical information to understand how Porex Virtek intensifies air disinfection.

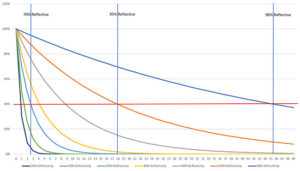

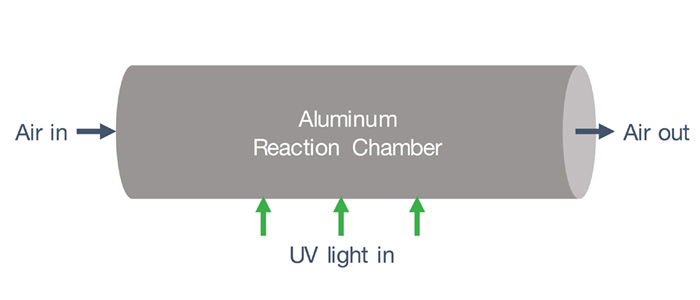

Flow Reactor Irradiance Comparison

Traditional Aluminum lining

Reactor Chamber with Aluminum lining

- Typical Reflectivity around 70%

- Specular reflection means hot and cold spots and uneven disinfection

- The orientation and quantity of UV source becomes much more important

- Energy needed for 3 log reduction increases

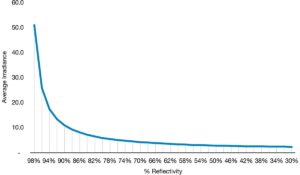

- Average irradiance (E) = (Edirect) + (Ereflected) :If Reflectivity = 70%

- At a source irradiance (E) of 1: Average irradiance = 1 + (1 / (1-0.7))= 4.3

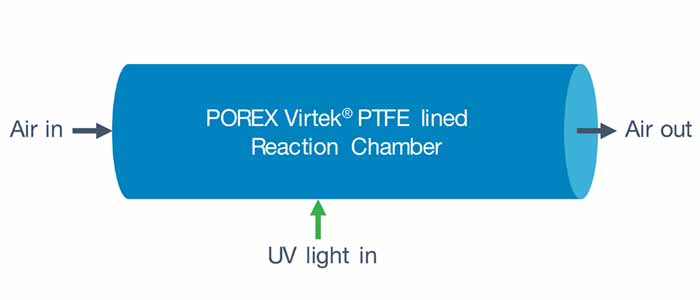

Optimal PTFE lining

Reactor Chamber with PTFE lining

- Reflectivity of up to 97%

- Reflects diffuses in all directions uniformly (minimal hot/cold spots)

- UV orientation less critical

- Energy consumption is lower

- Average irradiance (E) = (Edirect) + (Ereflected) :If Reflectivity = 97%

- At a source irradiance (E) of 1: Average irradiance = 1 + (1 / (1-0.97))= 34.3

- 8 times the average irradiance versus 70% aluminum!

Register for our On-Demand Webinar

Using Highly Reflective PTFE to Improve Efficacy of UV Air Disinfection Systems

Applications

HVAC Air Handling Systems:

Optimize efficiency and ensure maximum pathogen disinfection within your HVAC air handling system

- Highly diffuse reflectivity ensures extremely uniform UVC energy distribution

- Minimize hot and cold spots within the reaction chamber

- Increase effective pathogen deactivation rates by up to 4X versus other reflective media

- Highly reflective and durable down to 200 nm UVC wavelength

Self-Contained Air Purifiers:

Optimize efficiency and ensure maximum pathogen disinfection within your self-contained air purification system

- Highly diffuse reflectivity ensures extremely uniform UVC energy distribution

- Minimize hot and cold spots within the reaction chamber

- Increase effective pathogen deactivation rates by up to 4X versus other reflective media

- Highly reflective and durable down to 200 nm UVC wavelength

Personal Air Purifiers

Optimize efficiency and ensure maximum pathogen disinfection of personal UV air sterilization units

- Highly diffuse reflectivity ensures extremely uniform UVC energy distribution

- Minimize hot and cold spots within the reaction chamber

- Increase effective pathogen deactivation rates by up to 4X versus other reflective media

- Can be thermoformed into complex shapes or made into tubes to fit into tight areas

Related Resources

Porex Virtek® PTFE Highly Reflective UV Materials Brochure

Discover the benefits of Porex Virtek® PTFE UV reflective materials that enhance the efficiency of your UV disinfection system.

UVC Air Disinfection Chamber Demonstration – Porex® Virtek PTFE vs Aluminum & Plastic

A demonstration video that compares the effectiveness of Porex® Virtek PTFE to aluminum and plastic in UVC Air Disinfection Chambers.

UVC Disinfection Chamber Demonstration – Porex Virtek Lined Box vs Aluminum

Watch this demonstration video to witness how Porex Virtek PTFE demonstrates reflectivity readings that are 10 times higher compared to straight aluminum.

Comparing Specular and Diffuse Reflectivity

A demonstration video exploring the distinction between specular and diffuse reflectivity and its implications in UV disinfection.