Porous Fibers Innovation Expert

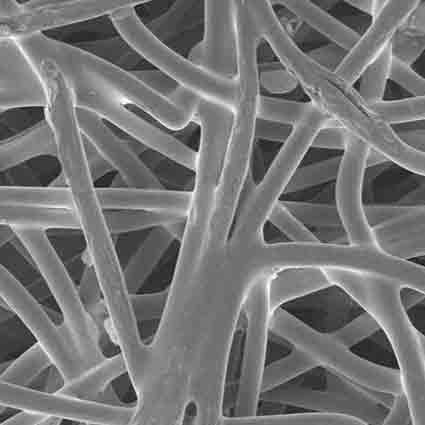

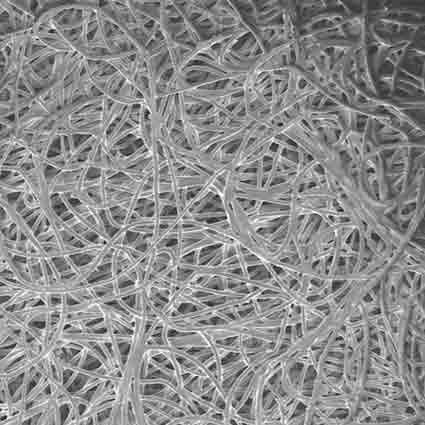

Porous fiber consists of bonded fibrous strands which create two-dimensional cross-sections that can be extruded to create three-dimensional shapes. Between the directionally aligned fibrous strands are voids, or pores, which can be independently controlled for fluid management applications that require faster flow or greater absorption of liquids.

These bicomponent fiber materials have an inner core and outer sheath that provide an ideal capillary structure for liquid transfer, filtration, and diffusion applications where wicking speed, wicking distance, filtration efficiency, and flow resistance are key drivers of the device’s performance.

Made from a variety of thermoplastic materials with varying properties, our materials are moldable for high-volume applications and customizable for easy fabrication and conversions. We provide large sheets, rolls, or other material formats specific to your needs.

Talk with a Material Science Expert

Manufacturing process

Porous fiber uses heat and pressure in the bonding process similar to sintered porous plastics. Instead of bonding particles, though, it bonds fibrous strands. A sheath is wrapped around customized fibers and the fibers are bonded in various configurations. This does not involve knitting or weaving, but rather forming fibrous components such as sheets, rods, tubes, blocks, and 3D geometrics.

Watch the process

Options for customizing porous fiber

Register for Our On-Demand Webinar

Intro to Porous Fiber

Common applications for porous fiber

Wick

Wicking works extremely well with porous fiber, as capillary forces are able to promote ease of fluid transfer in applications such as point-of-care diagnostic sample testing, dialysis treatments, and commercial applications such as inkjet printing cartridges.

Filter

Porous fibers can help to separate a solid or liquid from a mixture. Some of these applications include automotive oil & fuel water separation filters, injectable and applicator glass shard filters for life science applications, as well as liquid contaminant removal filters for consumer and industrial segments.

Diffuse

Porous fiber solutions can offer precision control over the diffusion rate in applications such as bioprocessing spargers, plug-in air fresheners, as well as insecticides.

Apply

Application products such as whiteboard marketers work great with porous fiber nibs. The material allows the ink to apply evenly and completely onto a surface or substrate.

Related Resources

Understanding the Fiber Bonding Process

The video demonstrates how Porex utilizes synthetic fiber binding processes to produce components.

What Is Porous Plastic?

Read how porous plastic is formed as a component to control the flow of gases, liquids, light, or sound.

Understanding Pore Size Distribution

In this video, learn how to measure the space between the particles and it’s effect on component performance.

Your Partner in Innovation

Discover how Porex has been a partner in innovation for over 60 years in this video.