Industrial Air Handling – Compressed Air

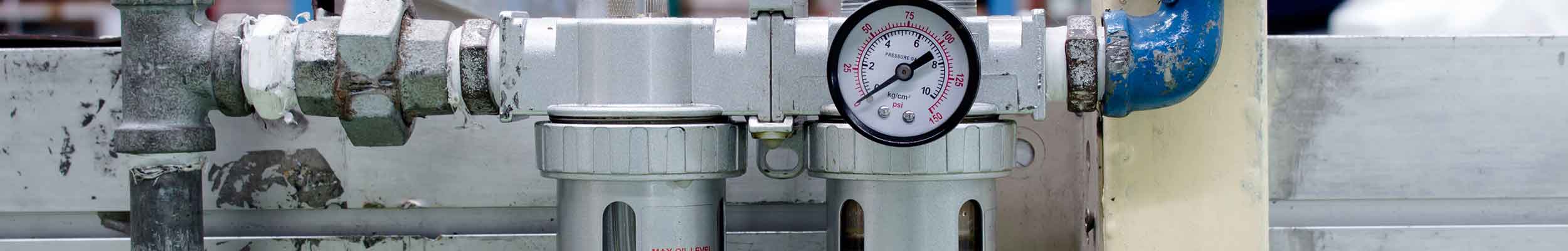

Manufacturers across the world choose POREX® filters and silencers to help meet filtration efficiency, airflow and pressure drop requirements.

As a cost-effective solution for pneumatic systems, our filters and silencers deliver a long life, clean air lines and superior noise attenuation, along with additional key benefits to help you succeed in today’s competitive global markets:

- Improve machine longevity with optimized design for greater reliability and efficiency.

- Enhance performance with customized designs to meet efficiency, airflow and pressure drop requirements.

Pneumatic Filters

Increase performance of your pneumatic systems

Pneumatic Silencers

Effectively reduce pneumatic equipment noise

Membrane Support

Strengthen and enhance membrane performance

Face Mask Foam

Greater comfort, sealing and support for facemask applications

Plastic Filter Housings

Protect vacuum equipment from corrosion and contamination

Pneumatic Filters

Increase performance of your pneumatic systems

Powering pneumatic machines requires clean and conditioned air or gas. Our pneumatic filters are designed to work together with regulators and lubricators (FRL units), to offer outstanding performance and a lower-cost alternative to traditional sintered-metal filters.

Specifically designed to provide an excellent combination of particulate filtration, air flow and back pressure performance, while complying with strength and aesthetic requirements, these single-component molded filters:

- Meet your filtration requirements – Optimized design meets filtration, airflow and pressure drop requirements.

- Reduce costs – Sintered polymer filters are more cost-effective than sintered metal.

- Improve machine longevity – Design is optimized for reliability, efficiency and longevity of pneumatic machinery.

Features

- Work together with regulators and lubricators (FRL units) to deliver clean and conditioned compressed air or gas

- Strong and rigid for maximum service life and effectiveness

- More cost effective than traditional sintered metal filters

Materials Offered

- Advanced porous materials (PE, PP)

Formats Available

- 3D molded shapes

Pneumatic Silencers

Effectively reduce pneumatic equipment noise

Engineered to provide an optimal balance between noise reduction and acceptable backpressure in the pneumatic system, our porous plastic silencers offer numerous advantages over metal acoustical silencers.

Our porous plastic silencers are designed with a significantly lower weight along with greatly improved corrosion resistance and the ability to filter particles and aerosols. This leads to greater durability, assembly speed and cost-efficiency for our partners. Designed with a solid integrated threaded adapter to ensure easy mounting on pneumatic equipment, our silencers:

- Fit most standard valves – Offered in an extensive selection of sizes designed to fit most standard valves, including NPT, BSP, M5 and “push-in” styles.

- Enhance equipment longevity – Effectively filters particulates and aerosols.

- Reduce pneumatic equipment noise – Engineered with a porous plastic structure, offering greater noise reduction compared to metal and improved corrosion resistance.

Features

- Provide an optimal balance between noise reduction and backpressure

- Lower weight, and improved corrosion resistance vs. metal acoustic silencers

- Integrated thread adaptor to ensure easy mounting on pneumatic equipment

Materials Offered

- Advanced porous materials (PE)

Formats Available

- 3D molded shapes

- Sizes designed to fit most standard valves including: NPT, BSP, M5 and “push-in” styles

Membrane Support

Strengthen and enhance membrane performance

Customized and developed for specific end-use applications, POREX® membrane support media are used as substrates for fragile membranes to provide structural strength and enhanced performance.

Available in polyethylene (PE) and various customized geometries, our membrane support media:

- Support fragile membranes with a strong and durable media.

- Enhance performance of specific end-use applications with custom designs

Materials Offered

- Advanced porous materials (PE)

Formats Available

- 3D molded shapes

- One piece solid and welded options including tubes and sheets

- Customization options for specific applications

Face Mask Foam

Greater comfort, sealing and support for face mask applications

Expect greater comfort and support for consumer and industrial face mask applications with POREX® latex-free foam.

Tailored for your application, our latex-free foam:

- Conforms to nasal and facial contours – Shapes to end-user nasal and facial contour for superior seal and fit, which enhances safety during use.

- Controls perspiration for added comfort

- Meets custom end-use requirements – Customized durometer, color and width to meet your face mask specifications.

Features

- Conforms to nasal-facial contour for maximum comfort and fit

- Latex-free and hypoallergenic

Materials Offered

- High purity polyurethane foam

Formats Available

- Customized size, durometer, color and width

Plastic Filter Housings

Protect vacuum equipment from corrosion and contamination

POREX® plastic filter housings are self-contained preliminary filters for both gases and fluids. Designed to protect vacuum equipment, pneumatic controls units, pumps and motors from corrosion and chemicals, our plastic filter housings are an economical pre-filtration alternative for potable water and reverse osmosis systems.

Available in different sizes and porosities, our plastic filter housings:

- Ensure quality performance – Plastic filter housings are FDA, Reach and RoHs certified.

- Available in multiple configurations with BSP and NPT thread types

POREX® Plastic Filter Housing Specifications

| Connection Size | Installation Depth (mm) | Installation Width (mm) | Overall Height (mm) | |

|---|---|---|---|---|

| PFH-L | 3/8″ | 112 | 90 | 125 |

| PFH-L | 1/2″ | 114 | 90 | 129 |

| PFH-L | 3/4″ | 116 | 90 | 135 |

| PFH-S | 1/8″ | 83 | 58 | 92 |

| PFH-S | 1/4″ | 84 | 74 | 94 |

| PFH-S | 3/8″ | 86 | 74 | 98 |

| PFH-S | 1/2″ | 87 | 74 | 101 |

| PFH-XS | 1/8″ | 48 | 58 | 57 |

| PFH-XS | 1/4″ | 49 | 74 | 59 |

| PFH-XS | 3/8″ | 51 | 74 | 63 |

| PFH-XS | 1/2″ | 53 | 74 | 67 |

Related Resources: ![]() Brochure: PLASTIC FILTER HOUSINGS

Brochure: PLASTIC FILTER HOUSINGS