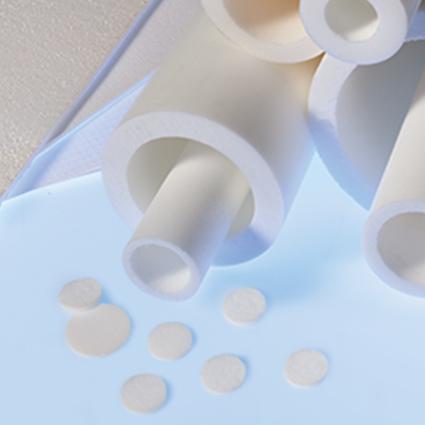

Robust and versatile media for single-use bioprocessing applications

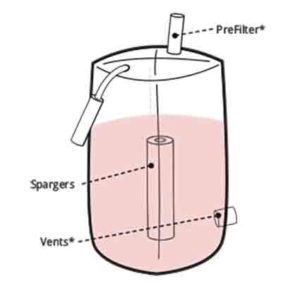

Our custom bioprocessing media and filters – including spargers, floating filters, wicks, vents, and pre-filters for tangential flow filtration – can be used in a wide range of applications.

As a complete porous materials solution, POREX® bioprocessing media provide critical functionality and performance in single-use bioprocessing applications.

Sparger Solutions for Effective Bioprocessing

As part of our extensive range of bioprocessing media and filters, we offer top-tier sparger solutions that provide exceptional performance in diverse bioprocessing applications. Our uniquely designed spargers are efficient in operation and constructed to adhere to strict engineering standards, thus making them an ideal choice for any engineer looking for reliable bioprocessing components.

For an optimized gas transfer, bubble size and distribution are key elements in sparger design. At POREX, we provide robust, customizable, sparger solutions with versatile performance, improving your bioprocessing systems’ efficiency.

Options for customizing porous bioprocessing media and filters

Watch our On-Demand Webinar

Using Porous Polymers for Filtration

Related Resources

Porex Bioprocessing Media and Filters

Explore Porex’s Bioprocessing Media and Filters, the intelligent porous materials that play a crucial role in enabling critical functionality within single-use bioprocessing.

Specialty Filtration Solutions Brochure

Explore the breadth of custom-engineered specialty filtration solutions designed to meet your unique filtration needs to provide critical functionality for single-use bioprocessing applications.

Porex – Your Partner in Medical Innovation Video

Watch this video to see the breadth of custom healthcare component innovation made from Porex’s porous polymers and material science expertise.

Enhancing Diffusion Capabilities – BioProcessing

Check out another brief video from our diffusion webinar to learn how this application works and what to consider when designing for diffusion.