Consumer Goods

Protection Vents for Portable Electronics

Porex Virtek® IP-rated protection vents

Portable Electronic Vents Tailored to Your Needs

From smartphones to electric toothbrushes, consumers use a multitude of electronic devices on a daily basis. For manufacturers of these devices, protecting the sealed, electronic components is critical to ensuring the device performs as intended and does not pose a safety risk to the end user. To protect these electronics in items like cell phones, digital cameras, headphones, wearables, and more, Porex can supply sintered Virtek® IP-rated protection vents to provide a tougher, more durable solution that can withstand handling, ultrasonic welding, and heat bonding without additional support material. In addition, these venting solutions can be customized by shape and performance needs – available as adhesive discs, sheets, rolls, and custom forms and shapes.

Portable electronics manufacturers know the importance of keeping their electronics running smoothly. To ensure a positive end-user experience, Porex’s high-performance Virtek® IP rated PTFE protective vents are designed to reduce pressure buildup while also providing protection against dust, water, sweat, and other contaminants.

Options for customizing protection vents for portable electronics

- Allows heat to escape electronic enclosures which can prevent premature failures

- Repels dust, water, sweat, oils, and other liquids from entering sealed electronic enclosures

- Sintered structure allows for ease of handling and welding – no cumbersome assembly instructions and processes that are typical with expanded PTFE

- 100% PFOA free – compliant with (EC) 1907/2006 REACH / Regulation (EU) 2019/1021 POP

POREX Virtek® PTFE Membrane — Typical Properties

| Item Number | IP Rating † | WEP* Typical mbar |

Typical Airflow l/hr/cm² @70mbar |

Filtration Efficiency** >99.99% |

Thickness mm |

Max Operating Temp °C |

UL-94/746C | Salt Fog$ |

|---|---|---|---|---|---|---|---|---|

| PMV10 | 64,67 | 270 | 107 | 0.5 µ | 0.13 | 260°C | V-0/f2 | No pen. |

| PMV10L*** | 64,67 | 270 | 85 | 0.5 µ | 0.3 | 100°C | – | No pen. |

| PMV15 | 64,67 | 370 | 75 | 0.4 µ | 0.18 | 260°C | V-0/f2 | No pen. |

| ‡PMV15T | 64,67 | 370 | 75 | 0.4 µ | 0.18 | 260°C | – | No pen. |

| PMV20 | 64,65,68 | 520 | 25 | 0.1 µ | 0.25 | 260°C | V-0/f2 | No pen. |

| PMV25 | 65,67,68 | 765 | 17 | 0.2 µ | 0.1 | 260°C | V-0/f2 | No pen. |

| PMV27 | 65,66,67,68 | 1050 | 7 | 0.1 µ | 0.19 | 260°C | V-0/f2 | No pen. |

*WEP = Water Entry Pressure

** According to IEST RP-CC007.2 2009

$ASTM B117-11 test method

***Laminated polyolefin mesh backing

‡ Oleophobic, AATCC TM 118 – Grade 8 – other membranes can also be treated to meet Grade 8 upon request

Properties are typical and not meant for specifications. Selected options and adhesives may effect properties

RoHS, WEEE, REACH Compliant (PFOA Free)

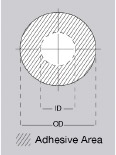

PRODUCT OFFERING BY MATERIAL SERIES – POREX Virtek® ADHESIVE DISCS

Dimenions (OD x ID in mm)

| Material Series | 5 x 2 mm* | 7 x 3 mm | 10 x 6 mm | 12.7 x 7.1 mm | 20 x 13 mm |

|---|---|---|---|---|---|

| PMV10 | PMV10M | PMV10N | PMV10P | PMV10W | PMV10C |

| PMV10L | PMV10LM | PMV10LN | PMV10LP | PMV10LW | PMV10LC |

| PMV15 | PMV15M | PMV15N | PMV15P | PMV15W | PMV15C |

| PMV20 | PMV20M | PMV20N | PMV20P | PMV20W | PMV20C |

| PMV27 | PMV27M | PMV27N | PMV27P | PMV27W | PMV27C |

| PMA10 | PMA10W# |

Special order items highlighted for higher MOQ. All others are stocked items

3M 93020LE adhesive standard (120 °C continuous use temperature

# Oleophobic treated and high temperature adhesive (good to 150 °C)

M, N, P, W & C are size codes as listed in column heading.

Many other standard and custom sizes available. Contact Porex for more information

POREX Virtek PTFE Vent Plugs — Typical Properties

| Item Number | Diameter mm (in.) |

Thickness mm (in.) |

WEP* mbar | IP Rating† | Typical Vent Airflow l/hr @70mbar |

Max Operating Temp °C |

Filtration Efficiency (99.99%) |

UL-94 Rating |

|---|---|---|---|---|---|---|---|---|

| PD103032 | 3.2 (1/8″) | 3 (1/8″) | 450 | 64,67,68 | 1 | 260°C | 0.5 µ | 5VA, f1 |

| PD103063 | 6.3 (1/4″) | 3 (1/8″) | 450 | 64,67,68 | 3.8 | 260°C | 0.5 µ | 5VA, f1 |

† IEC std. 60529; IP 68 is a user defined and results must be verified; product has not been specifically tested – passing is based on results from similar products

Assembly methods include: press fit, over-molding, compression seal, adhesive bonding or flange welding.

Numerous custom and standard options available. Please contact your local Porex sales representative to determine what is available.

Properties are typical and not meant for specifications.

RoHS, WEEE, and REACH Compliant (PFOA Free)

Related Resources

Why Your Electronics Need Proper Venting

Learn how Porex Virtek® can vent an electronic device to eliminate the pressure build-up with an IP protection vent.

Porex Virtek® IP-Rated Protection Vents Brochure

Explore the portfolio of robust Porex Virtek® IP-Rated Protection Vents across multiple applications for electronics.

What are IP Rated Protection Vents?

Learn what IP-rated protection vents are used for, what the IP rating means, and where to find them in products.

What Makes Your Smartphone Waterproof?

Explore how the porous vent ensures your smartphone remains impervious to water damage.

Select Samples

Explore our library of our most common capabilities samples to discover firsthand what is possible with custom materials.

Ask An Engineer

Take a first step by having a quick consultation with one of our application engineers.