Porex PTFE Hydrophobic Vents Act as Microfluidic Bubble Trap

Air bubbles are considered to be one of the most common design challenges associated with microfluidic devices used in point-of-care diagnostic testing. Poor bubble removal can impact quantitative measurements which can lead to improper device functioning and inaccurate optical readings. Porex Virtek® PTFE hydrophobic vents can successfully eliminate bubble occurrences – even in low vacuum conditions – and thus promote fluid flow through microchannels that otherwise may have become obstructed.

Porex Virtek® hydrophobic vent membranes support all debubbler microfluidics functions and microfluidic designs, from a true lab-on-chip PoC setting to lab-based molecular diagnostics.

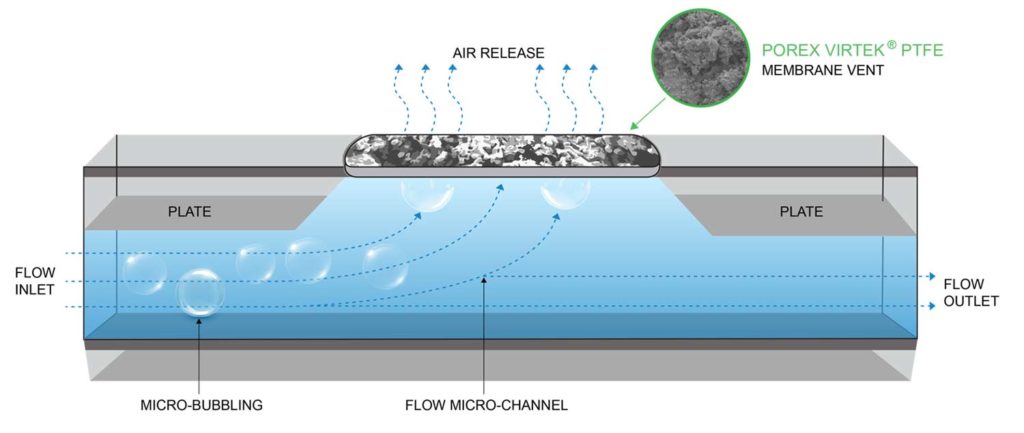

How it works

Porex Virtek® Hydrophobic Vents are permeable to gas but repel liquids – enabling an effective debubbling mechanism where:

- Air and fluid pressure migrate bubbles towards the vent membrane

- Bubbles release and break on the membrane surface

- Air passes through, yet the sample liquid does not pass

Register for our On-Demand Webinar

Technical & Design Challenges Integrating Porous Membranes in Microfluidics

Options for standard and custom microfluidic debubbler and vent membranes

Download our Tech Brief:

Microporous PTFE Successfully Degasses Air Bubbles in Microfluidic Devices

Related Resources

Porex Virtek® PTFE Material Selection for Microfluidic Devices

A tool to assist engineers in making accurate material selections for integrating Porex Virtek Hydrophobic PTFE venting materials into microfluidic devices.

Microfluidic Media and Filters Brochure

Explore custom microfluidic media and filters that serve as the smart enabling material that delivers filtration, wicking, and venting in lab-on-a-chip applications.

Diagnostics Video Series: Porous Polymer Solutions for Microfluidic Tests

Experience the various ways Porex Virtek microporous PTFE functions as a bubble trap (degassing or debubbling) in a microfluidic device.

Porex Virtek® PTFE Debubbling for Microfluidic Devices

This video showcases the functionality of Porex Virtek microporous PTFE as a bubble trap, for degassing or debubbling, in a microfluidic device.