Equalize Pressure While Minimizing Humidity Flow Using Porex Lighting Vents

From getting people to work to transporting goods, automobiles play a vital role in our daily lives and the global economy. Whether you’re driving in the early morning or late at night, having reliable and effective automotive lighting is essential for the safety of your vehicle’s occupants and other road users.

Porex understands the critical importance of automotive lighting and offers innovative solutions for lighting vents. Our specialized venting materials are designed to protect automotive lighting systems from moisture, dust, and other environmental contaminants that can compromise their performance. By integrating Porex’s high-quality venting solutions, automotive manufacturers can ensure that their lighting systems remain clear, functional, and reliable, even in demanding conditions.

Automotive Lights

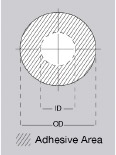

Without the fragility and variability common in non-sintered materials, POREX Virtek® PTFE, which is specifically designed for exterior automotive lights, uses unique sintered material that outperforms competitive expanded materials. With its robust porous structure, our vents equalize pressure while minimizing humidity flow into the enclosure, protecting enclosure seals from premature failure.

Related Resources

Porex Virtek® IP-Rated Protection Vents Brochure

Explore the portfolio of robust Porex Virtek® IP-Rated Protection Vents for electronics and automotive applications.

PTFE Venting Video Series: Durability comparison of Porex Virtek PTFE vs. expanded PTFE

Discover the unmatched strength and handling of Porex Virtek® Sintered PTFE compared to extended PTFE.

PTFE Venting Video Series: Dangers of Not Venting a Sealed Enclosure

Explore the risks and dangers associated with the lack of venting in a sealed enclosure.

PTFE Venting Video Series: Water Handling Demonstration – Porex Virtek PTFE vs ePTFE

A short video highlighting the hydrophobic properties of Porex Virtek® sintered PTFE over expanded PTFE (ePTFE).