Ensure properly disinfected water with Porex Virtek reflective media lining your UV water treatment systems

Keeping drinking water free of bacteria and pathogens is a global concern, and utilizing a UVC system within a complete water treatment system is one of the most effective ways to achieve this. UVC energy has been proven to deactivate most pathogens; however, to be effective, the UV energy must be uniformly dispersed within the reaction chamber. This is where Porex Virtek PTFE reflective media excels.

Porex Virtek offers:

- Reflectivity rates of up to 97%

- Almost 100% Lambertian (diffuse) reflectivity to ensure extremely uniform UVC energy distribution within the reaction chamber

- Minimized hot and cold spots within the reaction chamber

- Up to 4x higher flux in a closed system versus aluminum

- Increased effective pathogen deactivation rates, by up to 4X versus other reflective media

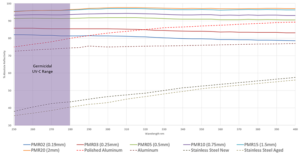

- High reflectivity and durability down to 200 nm UVC wavelength

Optimize efficiency and ensure maximum pathogen disinfection within your UV air disinfection system

UV disinfection chambers lined with Porex Virtek PTFE high-reflectivity media feature the Intensified with Porex Virtek logo, highlighting the efficacy of high reflectivity. Review our technical specifications and supporting technical information to understand how Porex Virtek intensifies air disinfection.

Flow Reactor Lining Considerations

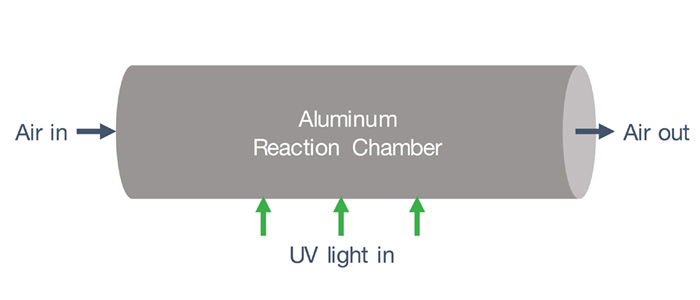

Traditional Aluminum lining

Reactor Chamber with Aluminum lining

- Little light bouncing so most of the work is done near the UV source

- More UV sources along the length are likely needed

- Specular reflection means hot and cold spots and uneven disinfection

- The orientation of the UV source becomes much more important

- Precise modeling of the flow becomes critical

- The shape of the reactor is important

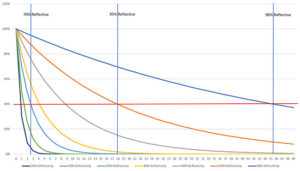

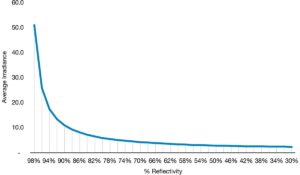

- Average irradiance (E) = (Edirect) + (Ereflected) :If Reflectivity = 35%

- At a source irradiance (E) of 1: Average irradiance = 1 + (1 / (1-0.35))= 2.5

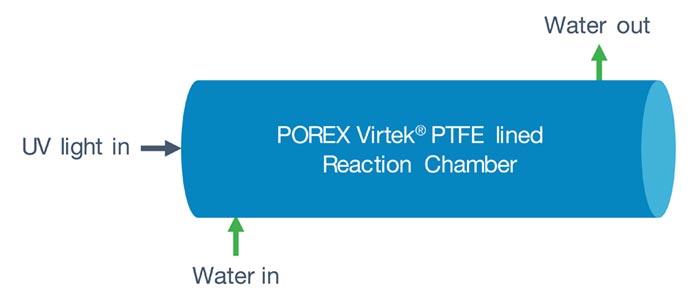

Optimal PTFE lining

Reactor Chamber with PTFE lining

- Light bounces around in all directions uniformly (minimal hot/cold spots)

- Energy losses are minimized

- The orientation of UV source is less critical and may not need multiple UV sources

- The shape and flow of the reactor become less critical as light bounces in all direction

- The shape of the reactor becomes less critical as light bounces in all directions

- Flow bypass becomes less of a concern

- Average irradiance (E) = (Edirect) + (Ereflected) :If Reflectivity = 97%

- At a source irradiance (E) of 1: Average irradiance = 1 + (1 / (1-0.97))= 34.3

- 14 times the average irradiance versus 35% stainless steel!

Applications

Water Disinfection Systems for Home or Point-of-Use (POU):

Adding a UVC system to a home water treatment process can provide an added level of confidence that the water is clean and safe to drink. Public water systems can vary in water quality and in many regions of the world, where even “clean” drinking water can cause illness and infection. Utilizing a UVC disinfection system lined with highly reflective Porex Virtek PTFE will ensure that a home / point-of-use (POU) system is working at peak efficiency and efficacy.

Water Disinfection Systems for Buildings:

It is becoming more common for water treatment facilities to include a UVC system. The UVC treatment process can provide an added level of confidence and reduce the amount of chemicals needed. Public water systems can vary in water quality in many regions of the world, so having an added layer of protection is key. Utilizing a UVC disinfection system lined with highly reflective Porex Virtek PTFE will ensure your system is working at peak efficiency and efficacy and can be several times more effective than simple stainless or aluminum-lined reactors.

Water Disinfection Systems for Personal Use

Increasingly, individuals want to know that the water they bring with them when they are on the go is safe and clean. Manufacturers have begun to offer caps for personal water bottles that incorporate UVC disinfection into the cap to reduce the possibility of pathogens that can cause illness and infection. Porex Virtek’s highly reflective PTFE is critical in this application as it ensures the UV energy is uniformly distributed within the container, for a higher level of consumer confidence.

Browse our Air Care Studies

Related Resources

Porex Virtek® PTFE Highly Reflective UV Materials Brochure

Discover the benefits of Porex Virtek® PTFE UV reflective materials that enhance the efficiency of your UV disinfection system.

UV Reflective Media Video Series: Porex High-Efficiency Diffuse Reflectors

Watch our practical demonstration video showcasing the efficiency of Porex Virtek PTFE reflective media. We compare the light output between a stock reflector and a Porex reflector.

UV Reflectivity Media Video Series: UVC Air Disinfection Chamber Demonstration – Porex® Virtek PTFE vs Aluminum & Plastic

A demonstration video that compares the effectiveness of Porex® Virtek PTFE to aluminum and plastic in UVC Air Disinfection Chambers.

UV Reflectivity Media Video Series: UVC Disinfection Chamber Demonstration – Porex Virtek Lined Box vs Aluminum

Watch this demonstration video to witness how Porext Virtek PTFE demonstrates reflectivity readings that are 10 times higher compared to straight aluminum.